Large shell structures made of concrete or

stone are hardly ever built any more. The reason is that their construction

requires large, expensive supporting structures. At the Vienna University of

Technology, a completely new construction method has been developed, which does

not require any timber structures at all: a flat concrete slab hardens on the

ground, and then an air cushion below the plate is inflated, bending the

concrete and quickly forming a sustainable shell. Even large event halls could

be built this way. In Vienna, a first experimental structure has now been built

using the new method.

"It is similar to an orange peel, which is

regularly cut and then flattened out on the table," says Professor Johann

Kollegger. "We do it the other way around, starting with a flat surface

and then bending it to a shell." Johann Kollegger and Benjamin Kromoser

(TU Vienna) have developed the new construction technique, which has now been

successfully tested on the Aspang Grounds in Vienna.

The Pneumatic Wedge Method

At first, a flat slab is created using standard

concrete. It is crucial to get the geometric shape exactly right. The slab

consists of several segments. Wedge-shaped spaces are left between these

segments, so that the segments fit together perfectly when the structure is

bent.

How it works:-

|

First, a number of flat rebar forms are laid out side-by-side on the ground at the building site, on top of a deflated plastic air cushion |

1.

First,

a number of flat rebar forms are laid out side-by-side on the ground at the

building site, on top of a deflated plastic air cushion (see the photo below).

Concrete is then poured into those forms and allowed to harden, resulting in a

series of flat slabs. Metal beams and a steel cable are subsequently attached

to those slabs, linking them all together.

|

Concrete is then poured into those forms and allowed to harden, resulting in a series of flat slabs |

2.

Next,

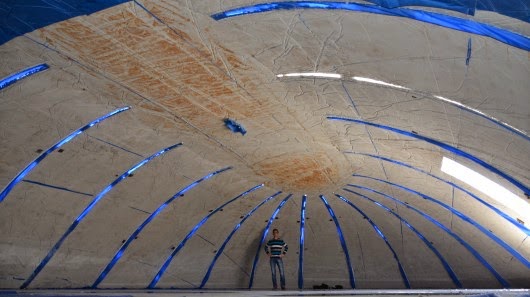

the dome-shaped air cushion is inflated. As it fills with air, it lifts the

slabs up from underneath, causing them to bend with it in the process. At the

same time, the cable is tightened in order to snug them in against one another,

with the connecting beams ensuring that they all move in unison. All of the

slabs have wedge-shaped edges, that allow them to securely interlock with their

neighbors.

|

As the air cushion inflates, it lifts the slabs up from underneath, causing them to bend with it in the process |

Once the slab is hardened, an air cushion below

is inflated. The cushion consists of two plastic sheets welded together. At the

same time, a steel cable is tightened around the concrete segments, so that the

concrete is lifted up at the center and pushed together from outside. To ensure

that all the concrete segments move in perfect synchronicity, they are

connected with metal beams. In the experiment, the whole process was finished

after about two hours, the final height of the concrete structure was 2.90m.

When the concrete is bent, many tiny cracks appear -- but this is not a problem

for the stability of the shell. "We can see that in old stone

arches," says Johann Kollegger. "If the shape is right, each stone

holds the others in place and the construction is stable." In the end, the

structure can be plastered, then it has just the same properties and is just as

stable as a concrete shell constructed in a conventional way.

Creative Freedom for

Architecture

"We decided not just to create a simple,

rotationally symmetric shape," says Benjamin Kromoser. "Our building

is a bit drawn-out, it cannot be described in simple geometric terms. We wanted

to show that using our technology, even complex free-form structures can be

created." Such playful free-form shells play an important role in

contemporary architecture. By carefully designing the shape of the concrete

slab and the air cushion, a wide variety of shapes can be built using the

pneumatic wedge method.

"Building shells with a diameter of 50

meters is no problem with this technique," says Johann Kollegger. The

hardest challenge is creating complicated shapes with a very small radius of

curvature. In the labs at TU Vienna, different kinds of reinforcement were

tested to see how strongly they can be bent -- a radius of curvature of just

three meters is feasible.

As the new construction method renders timber

structures obsolete, it not only helps to save time and resources, it also

saves a lot of money. Benjamin Kromoser estimates that about half of the

construction cost can be saved -- even more in large structures.

The team hopes that the new construction method

will establish itself on the market. It has already been patented. In the

meantime, the Austrian Federal Railways (OEBB-Infrastruktur AG) became

interested and commissioned a design project based on the new construction method

for a deer pass over two high speed rail tracks in Carinthia.

Comments