MS PROJECT FOR CONSTRUCTION SCHEDULERS

Table of Contents

List of Tables ................iii

List of Figures ................iv

Abstract ................v

1. Introduction ................1

2. MS Project Differences ................2

3. Tracking a schedule with MS Project ................4

3.1. Schedule Set-up ................5

3.2. Setting a Baseline ................8

3.3. Updating the schedule ................10

3.3.1. Updating Tasks ................10

3.3.2. Observing the Status Date ................15

3.3.2.1. Reschedule Uncompleted Work to Start After ................16

3.3.2.2. Status Date Calculation Options ................17

3.4. Comparing Schedules ................22

3.4.1. Identifying Variances ................22

3.4.2. Identifying Revisions ................23

4 Conclusion ................23

Bibliography ................25

Table 1, MSP Calculation Rules ................11

List of Figures

Figure 1 Remaining Duration in the Past ................3

Figure 2 MSP observes Data Date using constraints ................4

Figure 3 Recommended Status Date Selection Setting ................5

Figure 4 Schedule Options Tab ................6

Figure 5 Calculation Options Tab ................7

Figure 6 Set Baseline Screen ................9

Figure 7 Sample 10-Day Activity ................11

Figure 8 Result of Entering % Complete ................11

Figure 9 Result of Adjusting Remaining Duration ................12

Figure 10 Update Tasks Form ................12

Figure 11 Task Information Form ................13

Figure 12 Task Details Form ................13

Figure 13 Tracking Table ................14

Figure 14 Update Progress Screen ................15

Figure 15 Update Date Screen ................16

Figure 16 Status Date Screen ................17

Figure 17 Sample Schedule with Future Actual Dates ................17

Figure 18 Status Date Options ................17

Figure 19 Task with incomplete Work in the Past ................19

Figure 20 CPM Option to Move Incomplete Work Out of the Past ....19

Figure 21 Result of Moving Incomplete Work Out of the Past ...........19

Figure 22 Additional CPM Option for Incomplete Work ................19

Figure 23 Result of Moving Complete Work to the Status Date .........19

Figure 24 Sample Schedule with Complete Work in the Future .........20

Figure 25 Future Options ................20

Figure 26 Result of moving end of complete work back to status date 20

Figure 27 Sample Out of Sequence Progress ................21

Figure 28 Retained Logic ................21

Figure 29 Effects of Zero Remaining Duration ................21

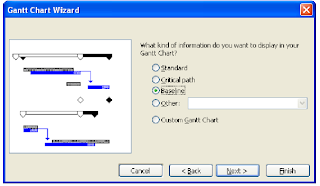

Figure 30 Gantt Chart Wizard ................22

Abstract

Despite some detractor’s opinions, Microsoft Project (MSP) CPM scheduling software is here to

stay as many contracts are now mandating its use. Most people using MSP on construction

projects find that MSP is fine for planning the work but very difficult to use when maintaining the

status and forecasting accurate project completion. MSP is also difficult to use when performing

delay analyses. The good news is that you can ‘make’ MSP properly reflect the consequences of an

update displaying proper Retained Logic. This paper will explain how to best use MSP in place of P6 or other more status-oriented scheduling software.

1. Introduction

Over the last two decades Primavera products became the predominant scheduling software of the

construction industry worldwide. Sadly, nothing lasts forever and many contracts have recently

started to specify MS Project (hereinafter referred to as, “MSP”) as the required scheduling

software.[1]

MSP has its advantages; it costs less than many of its competitors and it is ‘user-friendly’. It is easy

to start scheduling activities immediately. MSP easily produces decent default graphics and

reports. Another reason for MSP’s popularity is that a majority of US Federal Government PCs

come equipped with MSP. It is difficult to justify requesting the authority to purchase another

scheduling software when you already have one installed on your computer ‘for free’.

Most construction contracts for construction projects require periodic schedule updates. A

schedule update is an assessment of the project status and prediction of how and when the project

will be completed. Proper updating of the work schedule is an integral part of project management

and a critical communication tool between the parties. The schedule update should reflect the

current plan to reach project completion and an accurate record of the past performance. The

major steps in updating a schedule involve:

1. Setting a baseline

2. Updating the schedule

3. Comparing schedule updates

These steps are common to every software package and considered a regular course of business for

construction schedulers. MSP has many unique features specifically designed to make using the

software simple. However when it comes to updating a schedule using MSP, construction

schedulers often find MSP extremely confusing. This is mainly due to the MSP’s ‘ease of use

features’ getting in the way of reflecting the consequences of the current status. It gets even more

complicated if you ever have to do a forensic delay analysis on a MSP schedule. Cheer up, as all is

not lost. A clear understanding of how MSP calculates a schedule will make it possible to properly

use MS Project in place of a Primavera product, if needed.

This paper documents the complete process of tracking a schedule in MSP as well as the details of

how to ‘make’ MSP properly handle a typical status update involving out-of-sequence status.

2. MS Project Differences

There are a few operational differences between MSP and the Primavera products. Because MSP is

a Microsoft product, all work is performed in computer memory and you only save any changes

made if you tell the program to perform this operation. With products such as P6, all changes are

registered as soon as you press the Enter key. Because of the computer memory-centric scheme,

even in a multi-tasking environment of MSP Server, only one person can view the schedule at a

time.

MSP calls float values with the term, “Slack” and lists 0 as the value of slack for completed

activities. Finally, MSP only allows for one relationship between any two activities. This prevents

using the Start-to-Start and Finish-to-Finish relationship pairs found in P6 schedules.

MSP has unique concepts like Deadlines, and Recurring Tasks. In some cases, familiar scheduling

terms work different in MSP. For example “Multiple Critical Paths” in MSP means basically make

open ends critical. In some areas MSP lacks CPM functionality; for example the designation of a

longest path does not exist in MSP. For detailed explanation of MSP features and functionality, a

book such as Planning and Scheduling Using Microsoft Office Project 2007 [3] by Paul E. Harris can be consulted.

The differences in the internal computational factors are even more significant. It is crucial to

understand how MSP calculates the schedule before delving into the mechanics of statusing a

schedule. Since most construction schedulers are familiar with Primavera, it is easier to compare

MSP to Primavera to point out the major differences.

Primavera considers every activity in the schedule when computing a CPM, even those that are

statused as complete [2]. Unless overridden by a constraint, all activities without a predecessor are

scheduled (with consideration to their calendars) to begin on the current data date (early start) and

their remaining durations/relationships are used to compute their early finish. This rule even applies to completed activities with a remaining duration of zero. After all CPM calculations are complete, Primavera then goes back to the completed and in-progress activities and overrides the calculated dates with the actual dates. This process allows Primavera to consider the delaying effects of uncompleted work due to out-ofsequence progress under the Retained Logic calculation rule. Consequently, the Primavera Data

Date is the starting point and a fundamental piece of information for CPM calculation.

In contrast to P6, the default method of calculation for MSP does not require the scheduler to set a

Status Date (Primavera names it Data Date). This is simply, because MSP does not use the Status

Date to calculate the dates in the schedule. Instead MSP starts with the Project Start Date and

calculates the schedule using CPM rules even for the activities with actual dates. If an activity has

actual dates, the calculated CPM dates are ignored and the actual dates are used for calculating the

next activities’ start or finish dates. This is similar (but still different) to the P6 CPM calculation

mode, “Actual Dates.”

As shown in Figure 1 below, this process creates a potential for inherently flawed schedules with

remaining durations in the past or actual dates in the future. Both P6 and MSP suffer from allowing

actual dates in the future. P6 and MSP differ from how they handle incomplete work in the past.

Common sense and CPM rules require that activities with remaining duration scheduled in the past

must be ‘moved’ into the future. It defies logic to say “We will complete this work last month”.

Even though MSP is not designed to calculate the schedule from the Status Date, there are option

settings available in MSP to simulate CPM calculations based upon a Data Date. This somewhat

complicated process involves the use of built-in routines that add activity constraints and adjusts

some internal dates.

For MSP to simulate the effects of a Data Date, all unstarted tasks are given a Start-no-earlier-than

constraint date equal to the status date and all started but incomplete tasks have their Resume

Date set to the Status Date. This method delays the incomplete and unstarted tasks to the Status

Date. During this process, tasks with constraints lose their previously set constraints and tasks that

never had a constraint before now get a constraint. This is not desirable, but unfortunately it is the

only way that MSP observes the Data Date. Figure 2 below displays, the constraints assigned by

MSP to observe the Data Date.

3. Tracking a schedule with MS Project

The complete process of tracking a schedule involves setting a baseline, updating schedule status

and comparing the updates to the baseline or previous updates. For brevity, this paper assumes

that the reader is familiar with MSP user interface as well as its basic functionality and deals mainly

with general steps that an experienced construction scheduler would understand or expect.

Therefore starting with the schedule set up, we will cover setting a baseline, updating the schedule

and comparing the update to the baseline without detailed step by step instructions.

3.1. Schedule Set-up

Before explaining the details of schedule update process, it is crucial that the correct options are

selected and relevant points in time are displayed. MSP was designed to not rely on the Data Date.

There is Status Date which deceptively sounds like the Data Date in Primavera, but it is not the

same. Instead MSP relies on the Project Start date for calculation.

There is also a MSP Current Date which is the date of the computer when the file is open. If there

is no Status Date set then the Current Date is used for calculating earned value. Neither Current

Date nor the Status Date is used for calculating schedule dates and neither has any scheduling

significance. Neither of these dates is shown on the Gantt chart by default unless the user adds

them to the view. To reduce confusion, it is recommended that the Status Date line be displayed in

the Gantt views and Current date should not be displayed.

Figure 3 shows the recommended selection setting.

It is difficult and confusing to implement changes to the CPM calculation modes after an activity is

added. To prevent errors and confusion, we strongly recommend that you configure your MSP

schedule before adding the first activity. The recommended set-up steps are as follows,

- Under the Tools / Options / Schedule Tab. Figure 4 shows this tab.

Figure 4 – Schedule Options Tab

Split in-progress tasks: [Checked] This option allows rescheduling of remaining duration and work

when an in-progress task is running longer than originally planned.

Tasks will always honor their constraint dates: [Unchecked] This option tells MSP to schedule tasks

according to their constraint dates, regardless of logic. Clear the check box to specify that task

constraint dates with negative slack (float) move according to their relationships with other tasks

rather than be solely scheduled according to their constraint dates.

- Under the Tools / Options / Calculation Tab. Figure 5 shows this tab.

Figure 5 – Calculation Options Tab

Updating task status updates resource status: [Checked] This option insures that task resource

status does not override update status.

Move the end of completed parts back to status date: [Unchecked] This option prevents actual

dates later than the Status Date (in the future.) It also changes Actual Dates without user input.

This is dangerous to do. ‘Bad’ Actual dates should be flagged, but not automatically changed. P6

allows actual dates in the future but does note these as warnings in the Schedule Log produced.

and move start of remaining parts before the status date forward to status date: [Unchecked]

This option ‘recovers’ dangling work left over after moving completed parts back to the status date.

This step is unnecessary, as the remaining work will be scheduled after the Status Date.

Move the start of remaining parts before the status date forward to the status date: [Checked]

This option prevents uncompleted work from being scheduled before the Status Date (in the past.)

and move end of completed parts forward to status date: [Unchecked] This option will move

complete parts of split tasks to the status date and will assign new actual dates.

3. Because we are going to be splitting tasks, any tasks created must not be assigned Task Duration

Type of, “Fixed Duration.”

These options may NOT be turned on and off to recalculate all tasks. The options only work on new

tasks when they are added to a schedule or when a task is updated by changing the % Complete.

This is why we address these settings before you begin adding activities to your MSP schedule.

3.2. Setting a Baseline

Establishing a baseline is the first step in monitoring your schedule. The term, “Baseline” can be

confusing here as MSP (and P6) uses this word to mean something slightly different than from its

universal use in the construction industry.

The construction industry labels a schedule as a Baseline Schedule if it is the first approved,

complete schedule on the project. This type of Baseline typically does not have any status

recorded against it. MSP and P6 calls a baseline schedule any copy of the schedule that is stored

‘internally’ in another schedule. This type of baseline is used for comparison purposes. In this

paper, we will call the initial construction schedule a Baseline Schedule (using capitol letters) and

the MSP schedule copy, a baseline schedule (with lower case letters.)

When a baseline schedule is made, MSP copies Early Start and Early Finish dates to the baseline

Start and Finish Date fields. Original Duration gets copied to baseline Duration. Each Task’s Costs

and Work is copied to baseline Costs and Work fields. Nothing else is saved in a baseline schedule.

See Figure 6, Set Baseline Screen.

MSP treats the baseline as a snapshot of your schedule at the time that you created the baseline.

MSP does not store logic, float or constraints for the baseline and as a result, can not recalculate

any of the stored information. P6 users familiar with baselines will assume that they can convert

(or ‘unattach’) a baseline schedule back into a fully functional schedule. This is not the case with

MSP. Due to the fact that MSP baseline schedules do not store complete activity and logic

information, creating a MSP baseline is a ‘one-way’ process.

Baseline information can also be edited manually. Since baseline fields are editable by Users and

will not be recalculated by MSP, users should be cautious if they decide to change any of the

baseline information manually. The fact that it is all together too easy to accidently change this

information makes relying on the variance information more risky than with the typical

Target/Update procedure used with P3.

MSP allows for a maximum of 11 baselines. This is barely enough baseline storage for a 12-month

project without any Change Orders or Time Impact Analyses baselines. Users are strongly

encouraged to keep separate monthly backups in order to maintain and be able to prove past

status integrity.

There is also another MSP feature called, “Interim Plan” which has similar functionality as the

creation of baselines. This feature stores less information than a baseline. The Interim Plan

function only stores the Early Start and Early Finish dates of tasks and not durations, costs, or work.

An interim plan can be compared against a baseline plan or current plan to monitor project

progress or slippage. MSP allows up to 10 Interim Plans.

MSP allows Summary Tasks to be added, deleted, and moved around. If a task is added, deleted, or

moved after the baseline is set, the baseline dates for Summary Tasks become invalid. MSP has a

feature called Roll Up baselines that would reset the baseline dates for Summary Tasks.

Another important issue with the baseline is that the Late Start and Late Finish dates are not

stored. All variance measurements are assessed from the early dates. Available float

considerations are not taken into account and are not part of the baseline history.

3.3. Updating the schedule

3.3.1. Updating Tasks

The first step in updating the MSP schedule is to understand how durations are calculated. Task

durations are comprised of four important pieces of information:

1. Duration (which is equal to Actual + Remaining Duration)

2. Actual Duration

3. Remaining Duration

4. % Complete (which is equal to Actual Duration / Duration)

The calculation of MSP Actual and Remaining durations is confusing to many schedulers, especially for those who are used to Primavera products. First in Primavera, actual duration is calculated based the activity’s actual date and the Data Date (or Actual Finish date if it exists) whereas in MSP, the Status Date is not used in calculating actual durations.

Another reason for confusion is because MSP automatically links Duration, Actual Duration,

Remaining Duration and % Complete without an option to remove the link. Only any two of these

are independent, and the rest are calculated using the formulas listed above.

The scheduler needs to understand how these four pieces of information are calculated in MSP.

Table 1 below summarizes the interaction between these 4 duration-related task properties.

Table 1 – MSP Calculation Rules

To illustrate how each of these fields is calculated, let’s review a simple activity with 10-day

duration as shown in Figure 7.

Figure 7 – Sample 10-Day Activity

Entering 20% complete will automatically assign an Actual Start date and calculate the Actual

Entering 20% complete will automatically assign an Actual Start date and calculate the Actual

Duration and Remaining Duration. Actual Start will be set equal to the Start date (for unstarted

tasks, MSP Start date field equals to early start date) of the Task as shown in Figure 8.

Actual duration will be 2 days, which is 20% of the Duration. Remaining Duration will be 8 days which is Duration minus Actual Duration. If we further adjust remaining duration to 10 days, the Duration will become 12 days as shown in Figure 9. This is 10 days remaining plus 2 Days actual. % Complete will be 17%, which is Actual Duration divided by Duration.

Actual duration will be 2 days, which is 20% of the Duration. Remaining Duration will be 8 days which is Duration minus Actual Duration. If we further adjust remaining duration to 10 days, the Duration will become 12 days as shown in Figure 9. This is 10 days remaining plus 2 Days actual. % Complete will be 17%, which is Actual Duration divided by Duration.

Figure 9

MSP provides 4 different ways to enter actual data for each Task.

1) Using the Update Tasks Form as shown in Figure 10 is one way of entering actual data for each

task. This method is the least preferred method because the form has to be closed after updating

each task and opened again after selecting the next Task. This makes it very cumbersome to

MSP allows you to use this function to update multiple tasks at once but the limitation is that MSP

assigns the same value to all. Therefore unless all Tasks have the same update information, this

function is not useful.

2) Another available update method is using the Task Information form as shown in Figure 11. This

is also a cumbersome way of updating because the form has to be closed after each update and

Figure 11 – Task Information Form

3) Using the Task Details Form to update the schedule is a less cumbersome method compared the

previous 2 methods listed above. Task Details (as shown in Figure 12) can be opened by dragging

the divider line and selecting Task Details Form from View, More Views. If a Finish date is entered

without task being 100% complete, MSP will automatically add a Finish Constraint to the Task. For

this reason, this third option is also not recommended.

Figure 12 – Task Details Form

4) The easiest and most efficient method to enter activity actual date status is by using the Tracking

Table in the Gantt Chart or creating your own table as shown in Figure 13. It is recommended that

the following fields are shown on this custom table.

Once the detail tasks are updated, the summary tasks inherit status data from their detail tasks.

Actual start is assigned to the Summary task when a detail task has been given an actual start and

similarly Actual Finish is assigned when all detail tasks have been assigned actual dates. A

Summary Task’s % Complete is calculated by dividing the sum of all Detail Tasks Actual Durations by the sum of all Detail tasks Durations.

MSP has a somewhat unusual feature that allows the scheduler to manually update Summary

Tasks. It is unlikely that this feature will be used by construction schedulers. The reason that we

say this is that a manual update of a Summary Task affects all the detail tasks below it. If a %

Complete is entered at the Summary level, MSP assigns values for Actual Duration, % Complete,

Actual Start and Actual Finish all the children tasks (Summary or Detail). Calculation of these

values differs based on the “Updating Task Status Updates Resource Status” setting. If “Updating

Task Status Updates Resource Status” is checked, the tasks are statused as if they were completed

per plan. If not checked, then all of the children tasks get the same % Complete value of the

Summary task. This is obviously a dangerous procedure to employ if the accuracy of individual

activity status is desired.

MSP has a feature called Update Progress which will automatically update the activity as if it

progressed as planned. This feature automatically sets the Actual Start, Actual Finish, % Complete

and Remaining Durations. There are 2 options available under this feature as shown in Figure 14.

Set 0% -100% Complete - Selecting this option will set Actual date to Early Start. Actual Duration

and % Complete will calculated based on the date entered in “Update Work As Complete Through”.

date is later than Finish date of the Task. Selecting this option will not reset the Status Date.

Either of these options can be applied to the selected Tasks or for all Tasks in the schedule.

Scheduler must be careful using this feature for various reasons. First, if Set 0% or 100% Complete

option is selected, the “Update Work As Complete Through” date and the Status Date might not

match. To make things worse, remaining durations will not move to any of these two dates,

resulting in remaining durations scheduled to be complete in the past. Similarly, if this feature is

applied only to ‘Selected Tasks’ then there is a possibility that there will be unstarted activities in

the past. Set 0% -100% Complete would produce reliable results only if everything is going per

plan. Therefore this feature is very limited in its use and not recommended.

3.3.2. Observing the Status Date

As explained above, MSP was not designed to calculate estimated schedule dates using the Status

Date. Forcing MSP to observe the Status Date is very complicated process that requires

understanding the calculation options in conjunction with using the “Reschedule Uncompleted

Work” on the Update Project form.

3.3.2.1. Reschedule Uncompleted Work to Start After

To properly update a schedule first we need to understand “Reschedule Uncompleted Work to

Start After” feature available on the Project Update form shown in Figure 15.

Figure 15 – Update Date Screeen

Figure 15 – Update Date Screeen

For this feature to work properly, ‘Split in Progress Tasks’ must be selected under the Tools,

Options Schedule tab.

When this feature is used, MSP will go through each unstarted task and will assign a Start-No-

Earlier-than-Constraint equal to the Update Project Status date. Understand that MSP only allows

one early constraint per task. Because of this, if any of those unstarted tasks had a different

constraint, the existing constraint will be deleted in favor of adding the new CPM constraint. Tasks

that are in progress will have their Resume Date set to the Update Project date.

Another disadvantage to this process surfaces if one is required to destatus the project. To do so,

the scheduler has to review each activity and remove the constraints and adjust the task splits

manually. This makes it very difficult and time-consuming for analysts to perform schedule what-if

analyses.

In addition, MSP does not change the Status Date to the date specified in the Update Project

feature (Figure 15.) This often results in confusion as the date specified in Update Project screen

(Figure 16) is not displayed on the Gantt chart and might end up being a different date than the

one that is displayed. To avoid confusion and to display a correct Status Date on Gantt view, the

Figure 16

Scheduler should set the Status Date same as the date specified during Project Update function as

Scheduler should set the Status Date same as the date specified during Project Update function as

shown in Figure 15.

Coordinating the date between the two screens only solves half of the problem because it moves

in-progress activities after the Status Date. As shown below in Figure 17,

there still can be tasks in the future with actual dates. Unlike with P6, there is no automatic notice in the CPM computations report.

3.3.2.2. Status Date Calculation Options

MSP 2002 [4] and later versions have four CPM Options to force MSP to observe the Status Date. A combination of options under the Calculation tab is shown in Figure 18.

These options move tasks around the Status Date, change assign actual dates to automatically

prevent incomplete work in the past, and complete work in the future. These options based on

their titles seem self-explanatory but have unexpected consequences for the unwary scheduler.

First of all for these options to function properly one must ensure that:

• Split in Progress Tasks option must be selected,

• Desired options must be selected before tasks are added,

• Updating Task Status updates resource status option must be checked,

• Task Duration type must be something other than Fixed Duration.

These functions are limited because:

• The options only work on new tasks.

• The options only work if tasks are updated using % Complete. If the task has 0% progress,

these options will not apply therefore unstarted tasks in the past will remain in the past unless the

scheduler runs project update form “Reschedule Uncompleted Work to Start After” feature

• Changing the options will not recalculate the CPM to display the effects of that change.

• If a Status date is not defined, MSP will use the Current Date without warning the user.

Tasks only reflect the CPM options if the tasks are updated by using % Complete. Changes to task remaining duration will be reflected in the schedule, but not the effects of the changed option rules. Therefore if tasks are updated by using anything other than % Complete, these functions are not implemented, even if later set. This method of update is problematic as AACE Recommended Practice 53R-06 [5], recommends updating an activity’s status by indicating the new remaining duration estimate rather than indicating a new % Complete. Preventing Incomplete Work in the Past

Logic tells us that you should not display planned work prior to the Data Date. This inconsistency in

status ‘hides’ work that must still be completed, ignores required resources, and disrupts the

correct calculation of planned dates for future work.

To illustrate how these options work, let’s look at a simple schedule shown below in Figure 19

To prevent incomplete work in the past options shown in Figure 20 should be selected

With these options selected, entering a % Complete value would assign an Actual start and move

remaining part of the task after the Status Date as shown in Figure 21.

If the following option as shown in Figure 22 is checked

in addition to the one described above.

The task split will be removed, actual start date will be changed, and the complete portion of the

task will be moved to the Status Date as shown in Figure 23.

Figure 23

This option will override any previously assigned actual dates; therefore it is recommended that it

remains unchecked. Assigned actual dates should never be automatically deleted.

Preventing Complete Work in the Future

To illustrate how these options work, let’s look at a simple schedule shown below in Figure 24.

In this example start of Task 1 is constrained to start no earlier than 20SEP10.

To prevent complete work in the future options shown in Figure 25

should be selected.

If the task is updated by entering a % Complete, the actual duration portion of the task will be

moved to the Status Date and an actual date to match will automatically be assigned to the task.

Selecting “And move start of remaining parts back to Status Date” sounds like the “Progress

Override” option in Primavera products. This is not correct as this option will also override existing

constraints. If the task has a constraint, selecting this option will erase it and bring the remaining

part of the task back to the status date.

The Results of our Settings

Now that we have our activities observing the Data Date, we need to compare this to what is

presented in P6 software. For demonstration purposes, we will take the typical 4-activity schedule

with out-of-sequence progress like that as shown in Figure 27 below.

When the out-of-sequence activity (in this case, Activity 2) has some remaining duration, then the

CPM Calculation Options forces the schedule to resemble Retained Logic as seen in Figure 28

below,

When the same out-of-sequence activity has no remaining duration, then the CPM Calculation

Options forces the schedule to resemble Progress Override as seen in Figure 29 below.

This ‘hybrid’ behavior is similar to that displayed with the P6 Actual Dates CPM calculation option.

As seen with the examples above, using these options has serious implications of automatically

changing or assigning Actual Dates. Therefore the scheduler should clearly understand these

options before using them. If the scheduler is not comfortable with these options, the same results

can be achieved by using the “Reschedule Uncompleted Work to Start After” on the Update Project

form except for preventing Actual Dates in the future.

Activities with progress that are in the future can be identified by running a filter and then can be

manually corrected. This is no different than using Primavera products since none of the Primavera

products have a built-in feature to prevent assigning actual dates in the future.

3.4. Comparing Schedules

It is important to realize that there will be changes to the schedule logic as well as differences

between the planned progress and actual progress. Changes to the schedule logic and planned

durations are revisions to the schedule and they will be calculated to take place in future to the

right of the status date. Other variances due to the performance will be in the past to the left of

the data date. Variances in the performance should be handled separately from the logic revisions

and planned duration changes.

3.4.1. Identifying Variances

To identify variances in performance, Start Variance and Finish Variance columns can be used. In

addition, schedulers can create custom bar styles to display baseline and schedule update

information in the same view. MSP has a Gantt chart wizard (Figure 30) that allows users to create

these views easily and quickly however schedulers should be aware that using this wizard will

overwrite any existing custom formatting.

For a more detailed analysis, the actual dates and planned dates can easily be extracted from MSP

and moved to an Excel spreadsheet or to MS Access database to perform a Daily Delay Measure

analysis (MIP 3.2) [6] This can be further automated using Excel or Access formulas and macros.

Remember, that we can only note variances to the early dates and not the late dates. Variance

analysis cannot take activity float into consideration.

Figure 30 – Gantt Chart Wizard

3.4.2. Identifying Revisions

MSP 2007 has a Compare Project Versions utility to review differences between two similar MSP

schedules. The Compare Project Versions utility compares tasks and resources only and does not

compare resource assignments. This utility produces a comparison report which looks like a

project schedule. Although this report displays color coding and indicators that provide

information about tasks and resources, it is extremely hard to understand, especially for schedulers

who have been using Claim Digger or SureChange.

On the other hand, MSP has a powerful Visual Basic for Applications (VBA) programming language which allows a quick development for custom comparison software. MSP users can create their own comparison routines and easily create their own variance reports. Exporting schedules to MS Access and using it to compare the two similar schedules is another option open to the scheduler. A quick survey noted third-party software providers who specialize in MSP comparison tools to include the following,

• Acumen Fuse

• Project Analyzer

4 Conclusion

MSP is inexpensive, very user friendly (especially for beginners) and provides decent default

reports and graphs. A casual user of MS Office with no scheduling experience can pick MSP up and

quickly create schedules. However a seasoned scheduler working on a construction contract is

likely to struggle with updating and maintaining the schedule. Some of the “ease of use” features

function at the expense of the CPM theory, which become sources of confusion for a seasoned

scheduler. The main areas are:

1) MSP Baseline management is cumbersome and confusing for the average scheduler.

2) MSP updating method of using % Complete is not suitable for construction schedules.

3) MSP Data Date issues which in effect complicate the schedule update process are confusing for construction schedulers.

4) Due to the difficulty of using MSP to note uncompleted work before the Data Date, the difficulties in removing status for what-ifs, and the difficulty in identifying variances between a series of MSP schedules, it is hard to do most types of delay analysis (except perhaps RP 29R-03 [6] MIP 3.1 and 3.2)

5) Due to all of the built-in update help routines that automatically insert made-up actual dates and remaining durations, it is difficult to assume that most MSP schedules contain accurate enough status data that is necessary for a detailed analysis.

Of course this does not mean that MSP cannot be used for construction scheduling. MSP is here to stay as many contracts are now mandating its use. This only means that construction schedulers must be proficient in MSP in addition to the Primavera products.

Comments

MS Project Training

bestpmptraininginchennai